About Double Girder EOT Cranes

Double Girder E.O.T. Crane is one of the most common types of Electric overhead crane used or called Double Bridge Crane, which consist of parallel runways with a travelling bridge spanning the gap known as “Span”. As obvious from the name, Double Girder E.O.T. Crane is operated electrically, generally there is an operator cabin or a control pendant along with the E.O.T. Crane.

Double Girder E.O.T. Crane is commonly used in the refinement of steel and other metals such as copper and aluminium. At every step of the manufacturing process, until it leaves a factory as a finished product. The automobile industry uses overhead cranes to handle raw materials.

Almost all Paper mills, Sugar mills, Plastic moulding industry, Power Plants, Fabrication units etc. use Double Girder E.O.T. Crane for regular maintenance and General usage needing movement of heavy equipment and material.

Double Girder EOT Cranes

Technical Features

| Varied lifting capacities available |

| Excellent function performance |

| Superior quality materials |

| Easy to install process |

| Higher hook lift |

| Cost effective facility |

| Rugged construction |

| Easy to operate |

Special Features

| Specially designed for the specific needs of the Clients. |

| Fail proof cranes can be made in special cases for special usages with zero down time. |

| Loads can be distributed easily with the increase in number of wheels. |

| Capacity ranging up to 500T. |

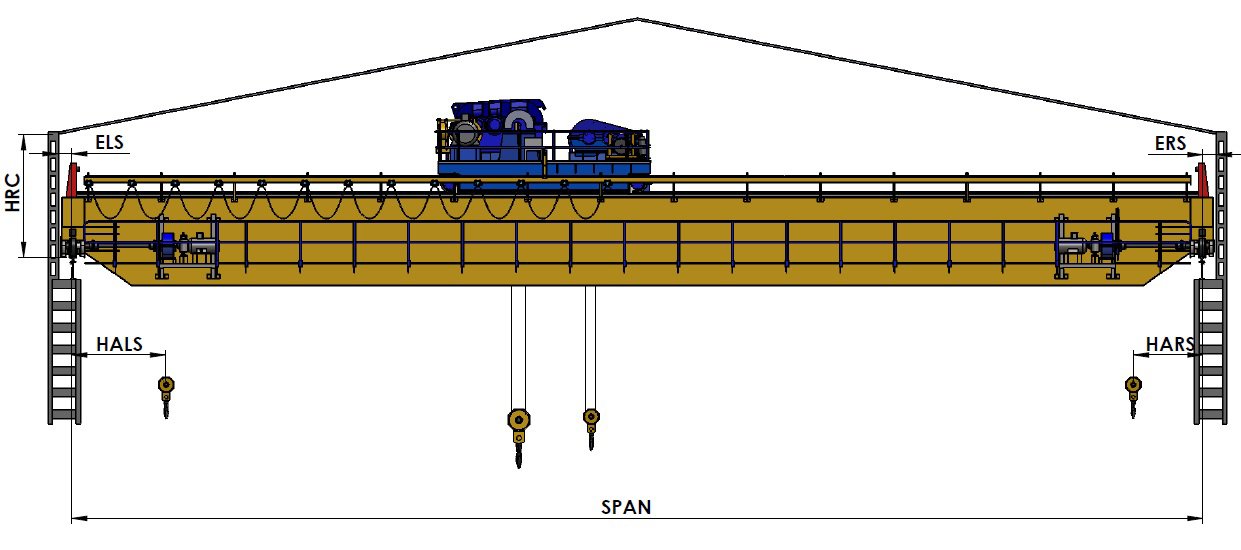

Double Girder EOT Cranes Diagram

Technical Data for Double Beam EOT Cranes

Below mentioned specification are subject to change without any prior intimation for the betterment of the product ( dated March 2017)

| Capacity in Tons | Span in Metres | Head Room Clearance in mm HRC | Hook approach in mm HALS | Hook approach in mm HARS | End Clearance in mm ELS/ERS | Wheel Base in mm | Total Wt. of Crane in tons (approx.) | Wheel load of crane in tons (approx.) |

| 5 | 10 | 1600 | 900 | 800 | 250 | 3800 | 10 | 5 |

| 15 | 1600 | 900 | 800 | 250 | 4000 | 13 | 6 | |

| 20 | 1700 | 900 | 800 | 250 | 4200 | 15 | 7 | |

| 7.5 | 10 | 1600 | 950 | 850 | 250 | 3800 | 13 | 7 |

| 15 | 1600 | 950 | 850 | 250 | 4000 | 17 | 8 | |

| 20 | 1700 | 950 | 850 | 250 | 4200 | 19 | 9 | |

| 10 | 10 | 1800 | 1000 | 900 | 250 | 4800 | 14 | 9 |

| 15 | 1800 | 1000 | 900 | 250 | 4900 | 17 | 10 | |

| 20 | 1900 | 1000 | 900 | 250 | 5000 | 19 | 10 | |

| 15 | 10 | 2000 | 1000 | 900 | 275 | 5000 | 19 | 12 |

| 15 | 2200 | 1000 | 900 | 275 | 5000 | 22 | 13 | |

| 20 | 2300 | 1000 | 900 | 300 | 5200 | 25 | 14 | |

| 20 | 15 | 2400 | 1100 | 900 | 300 | 5200 | 26 | 16 |

| 20 | 2500 | 1150 | 900 | 300 | 5300 | 30 | 17 | |

| 25 | 15 | 2600 | 1150 | 1000 | 300 | 5200 | 33 | 19 |

| 20 | 2800 | 1150 | 1000 | 300 | 5400 | 38 | 20 | |

| 30 | 15 | 2800 | 1200 | 1000 | 300 | 5200 | 30 | 22 |

| 20 | 3000 | 1200 | 1000 | 300 | 5400 | 37 | 25 | |

| 35 | 15 | 3000 | 1250 | 1050 | 300 | 5200 | 33 | 25 |

| 20 | 3100 | 1250 | 1050 | 320 | 5400 | 38 | 27 | |

| 40 | 15 | 3000 | 1300 | 1050 | 325 | 5300 | 36 | 28 |

| 20 | 3200 | 1300 | 1050 | 325 | 5000 | 40 | 30 | |

| 50 | 15 | 3200 | 1400 | 1100 | 350 | 5200 | 41 | 33 |

| 20 | 3500 | 1400 | 1100 | 350 | 5500 | 47 | 36 | |

| 60 | 15 | 3800 | 1600 | 1200 | 400 | 5600 | 60 | 43 |

| 20 | 4000 | 1600 | 1200 | 400 | 5800 | 72 | 47 | |

| 80 | 15 | 4000 | 1900 | 1300 | 450 | 5600 | 78 | 56 |

| 20 | 4200 | 1900 | 1300 | 450 | 5800 | 90 | 61 | |

| 100 | 15 | 4200 | 1900 | 1400 | 450 | 5800 | 95 | 69 |

| 20 | 1500 | 1900 | 1400 | 450 | 6000 | 111 | 75 | |

| 125 | 15 | 4200 | 2000 | 1500 | 450 | 6100 | 120 | 84 |

| 20 | 4500 | 2000 | 1500 | 450 | 6100 | 130 | 90 | |

| 150 | 15 | 4300 | 2000 | 1500 | 450 | 6200 | 145 | 101 |

| 20 | 4600 | 2100 | 1500 | 450 | 6200 | 155 | 108 |